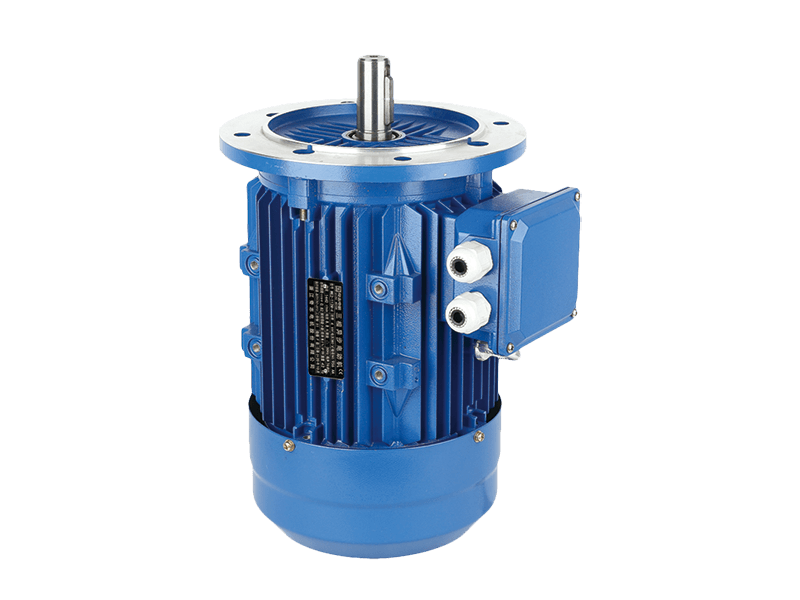

In the field of motor manufacturing, as an asynchronous motor manufacturer, we understand the importance of innovation and expertise. Today we want to take a closer look at a special type of asynchronous motor - the dual-capacitor induction motor. With its unique design and performance, this motor plays an important role in industrial and commercial applications.

A dual capacitor induction motor, as the name suggests, is an asynchronous motor that uses two capacitors in its circuit. This design allows the motor to have different characteristics when starting and running, improving efficiency and performance. As an asynchronous motor manufacturer, we are committed to producing high-quality dual capacitor induction motors to meet the needs of different customers.

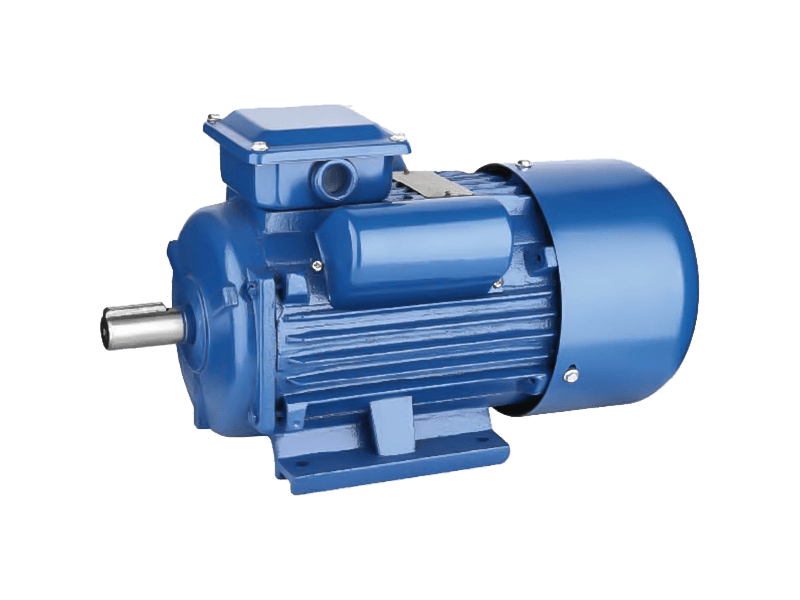

Let's start with the basic principles of dual capacitor induction motors. The working principle of this motor is based on the principle of electromagnetic induction, which means that when a conductor moves in a changing magnetic field, an electric current is generated in the conductor. In a dual capacitor induction motor, we use a main winding and an auxiliary winding, both of which are embedded in the stator of the motor. When AC power is connected to the main winding, it creates a rotating magnetic field. This rotating magnetic field interacts with the conductors on the rotor to create a torque that causes the rotor to rotate.

However, a unique feature of a dual-capacitor induction motor is its use of capacitors during the start-up and running phases. During the start-up phase, both capacitors are connected to the auxiliary winding, which increases the current in the auxiliary winding, thereby producing a larger rotating magnetic field. This design allows the motor to deliver more torque at start-up, which is critical for starting heavy-duty applications. As an asynchronous motor manufacturer, we understand the importance of providing strong starting torque in a variety of applications.

Once the motor reaches close to its rated speed, the auxiliary capacitor is disconnected from the circuit, leaving only the main capacitor to continue functioning. This conversion makes the motor more efficient during the operating phase, since the auxiliary capacitor no longer consumes additional power. This design not only improves the performance of the motor, but also helps reduce energy consumption, which is an important consideration for us as an asynchronous motor manufacturer.

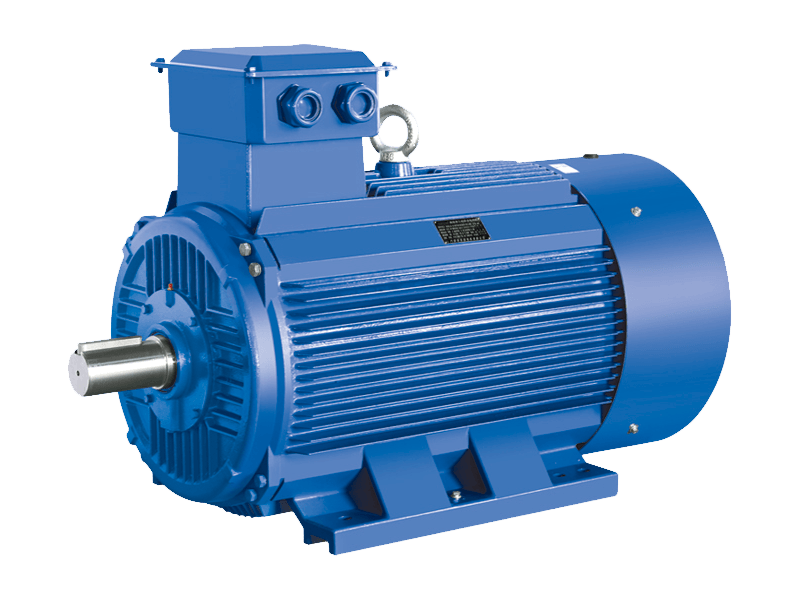

Another advantage of dual-capacitor induction motors is their reliability and durability. Since the starting and running characteristics of the motor are separated, this reduces the wear of the motor during the starting process, thereby extending the service life of the motor. As an asynchronous motor manufacturer, we are committed to producing durable and reliable motors to ensure that our customers benefit in the long term.

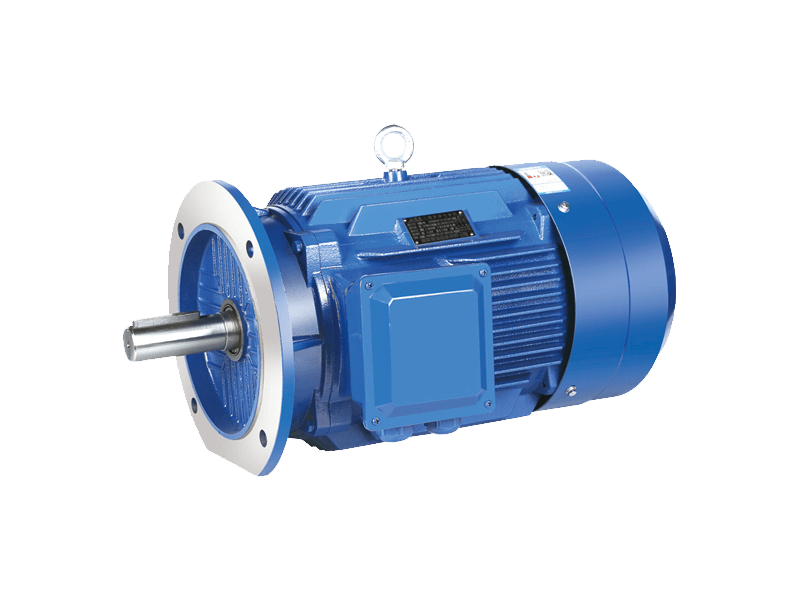

In addition, the dual-capacitor induction motor also has good speed regulation performance. By adjusting the value of the auxiliary capacitor, we can change the operating characteristics of the motor to achieve different speeds. This flexibility makes dual capacitor induction motors suitable for applications requiring precise speed control, such as conveyors, fans and pumps.

In terms of safety, dual capacitor induction motors also excel. Since the starting and running characteristics of the motor are separated, this reduces the current surge to the motor during starting, thereby reducing the risk of overload and short circuit. As an asynchronous motor manufacturer, we always put safety as the top priority in our design and production processes.

In summary, dual capacitor induction motors are an efficient, reliable and environmentally friendly motor type. As an asynchronous motor manufacturer, we are committed to producing such motors to meet the needs of our customers and promote the development of motor technology.