In industries where flammable gases, vapors, or dust are present, the use of explosion proof motors is critical for ensuring safety and preventing catastrophic incidents. These specialized motors are designed to operate in environments where the risk of explosion is significant, such as in the oil and gas sector, chemical manufacturing, mining, and food processing. Understanding the applications and importance of explosion proof motors in these industries is essential for maintaining safety standards and protecting both personnel and equipment.

In the oil and gas industry, explosion proof motors are indispensable due to the volatile nature of the materials handled. The extraction and processing of oil and gas often involve the presence of flammable gases, which can easily ignite if exposed to sparks or high temperatures. Explosion proof motors are constructed to contain any potential explosion within the motor itself, preventing the ignition of surrounding gases. This containment feature is crucial in drilling operations, refineries, and storage facilities, where the risk of explosion is heightened. By using explosion proof motors, companies can significantly reduce the likelihood of accidents, ensuring a safer working environment for their employees.

Similarly, the chemical manufacturing industry poses significant risks due to the handling of hazardous materials. Many chemicals are inherently flammable or can produce explosive vapors when mixed with air. In this context, explosion proof motors are vital for equipment such as mixers, pumps, and conveyors that are used in the production process. These motors are designed to withstand harsh conditions and prevent the ignition of flammable substances. By implementing explosion proof motors, chemical manufacturers can enhance safety protocols and comply with regulatory standards, ultimately protecting their workforce and minimizing the risk of costly accidents.

Mining operations also rely heavily on explosion proof motors, particularly in underground environments where methane gas and coal dust are prevalent. The presence of these hazardous materials creates a high risk of explosion, making it essential to use equipment that can operate safely in such conditions. Explosion proof motors are utilized in various mining applications, including ventilation systems, conveyors, and drilling equipment. These motors are engineered to prevent sparks and overheating, ensuring that they do not become a source of ignition in potentially explosive atmospheres. By integrating explosion proof motors into their operations, mining companies can safeguard their workers and maintain compliance with safety regulations.

In the food processing industry, explosion proof motors are increasingly being recognized for their importance in maintaining safety standards. While food processing may not seem as hazardous as oil or chemical industries, the presence of dust from grains, sugars, and other food products can create explosive environments. Additionally, the use of certain cleaning agents and chemicals in food processing can also pose risks. Explosion proof motors are used in equipment such as mixers, blenders, and packaging machines to ensure that operations can continue safely without the risk of igniting flammable dust or vapors. By utilizing explosion proof motors, food manufacturers can protect their facilities and employees while ensuring compliance with health and safety regulations.

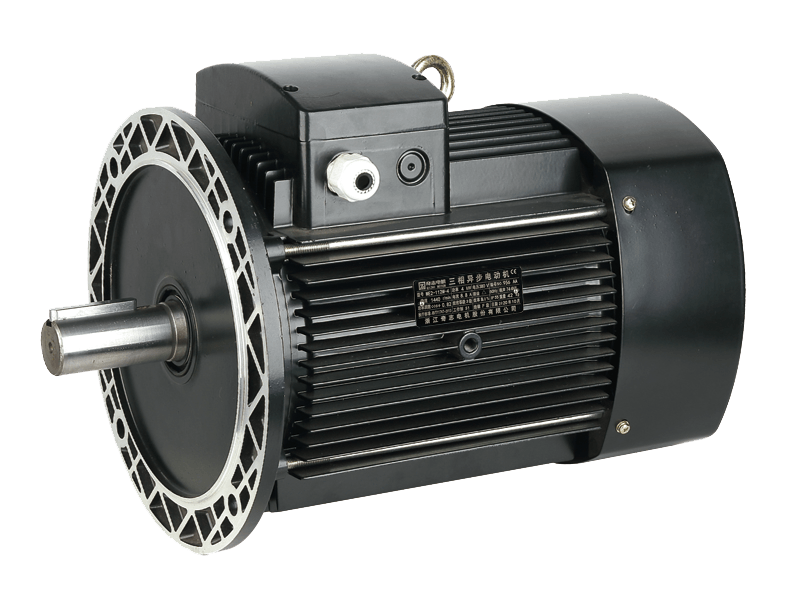

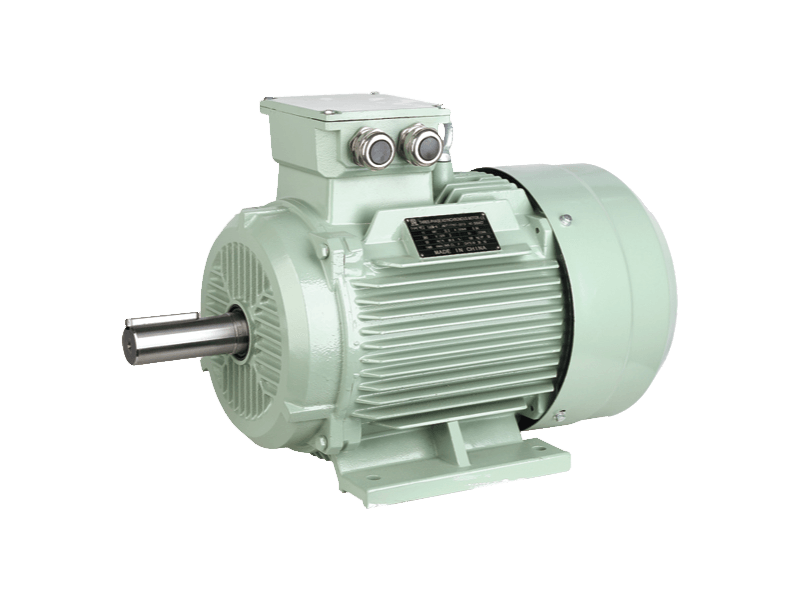

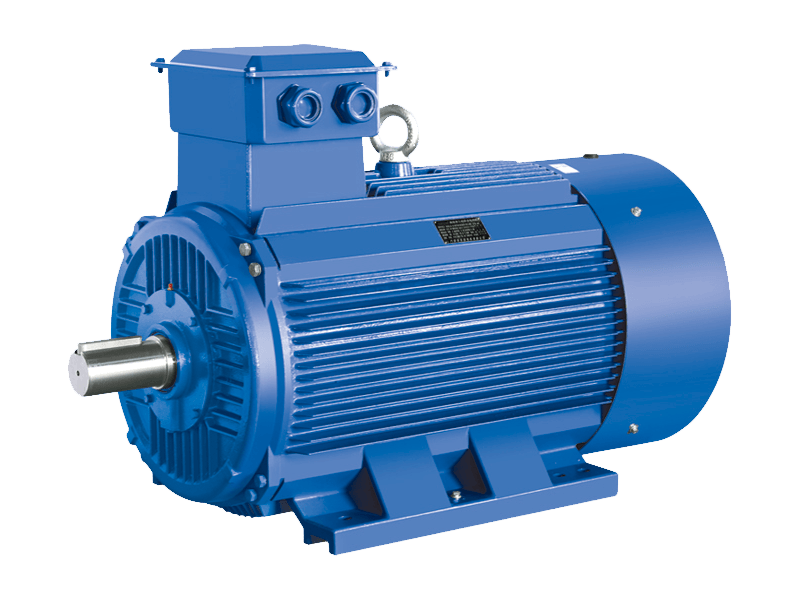

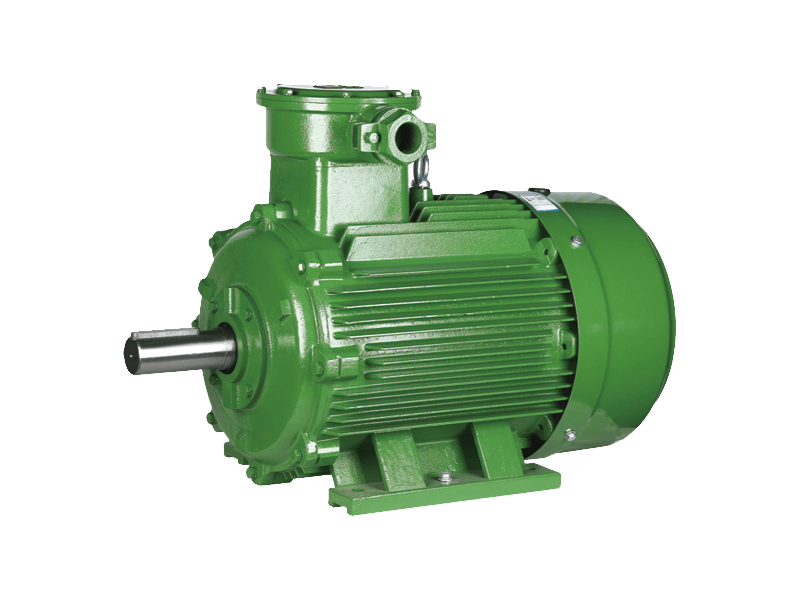

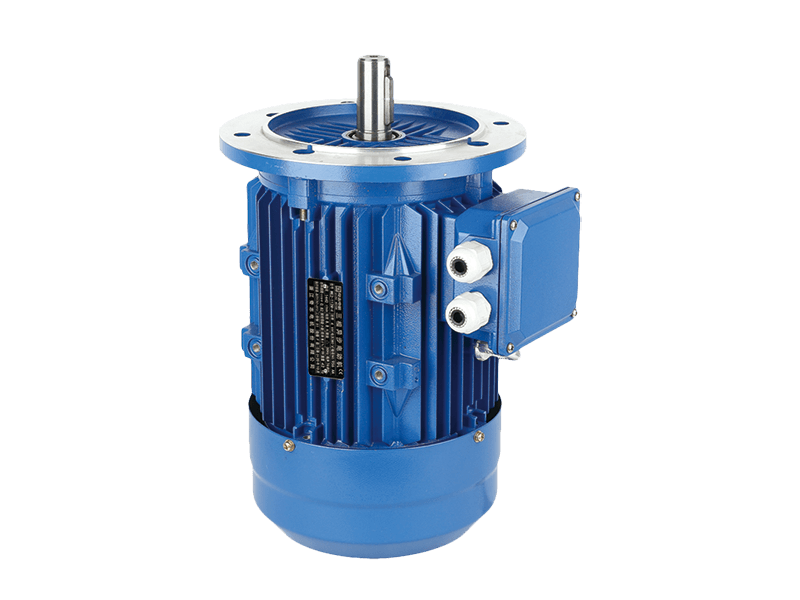

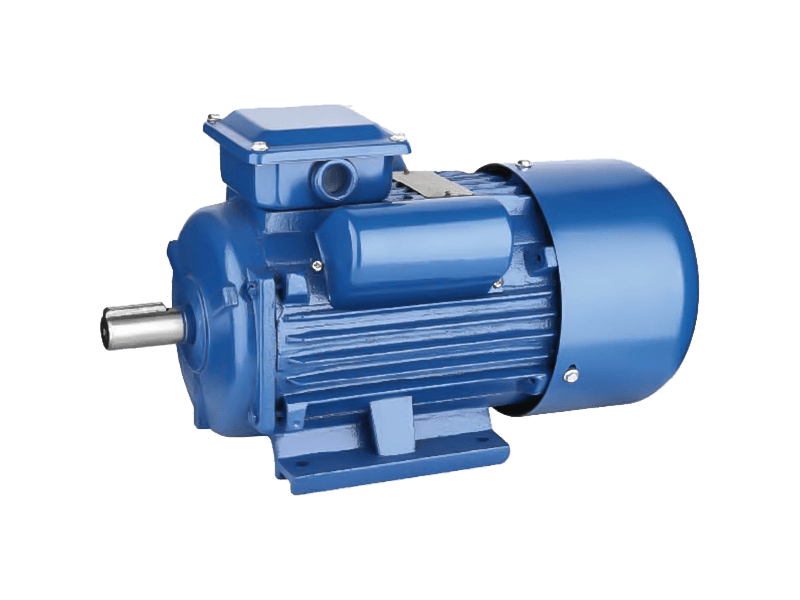

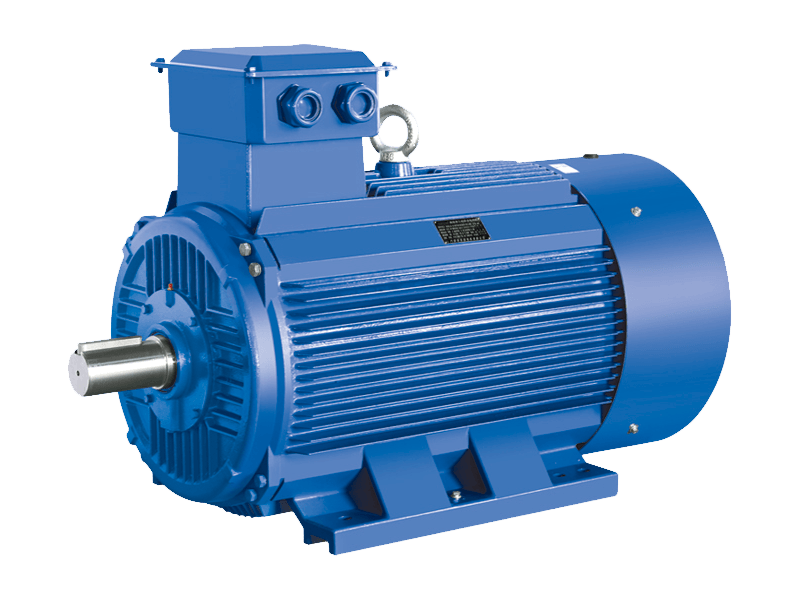

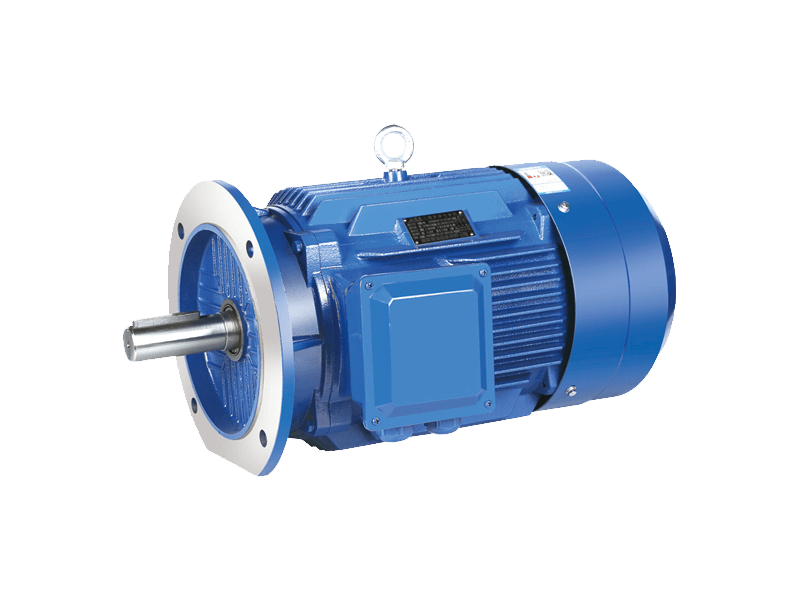

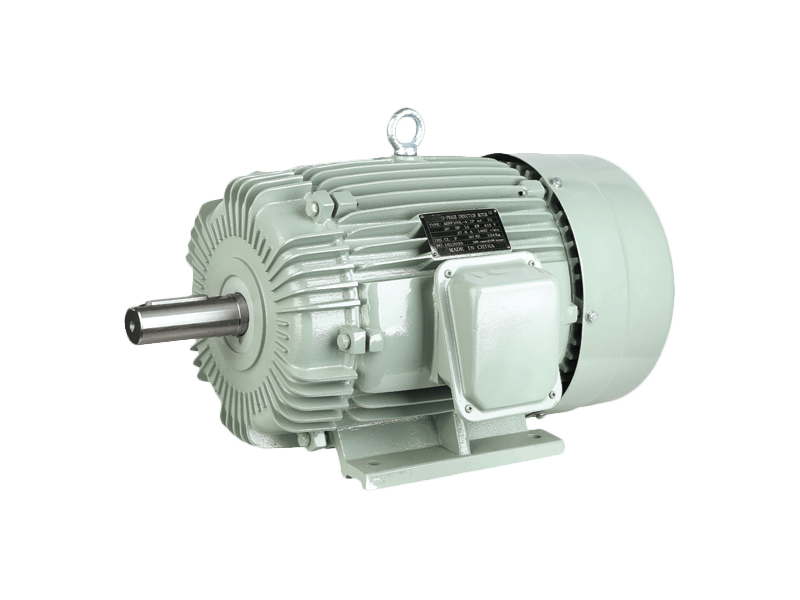

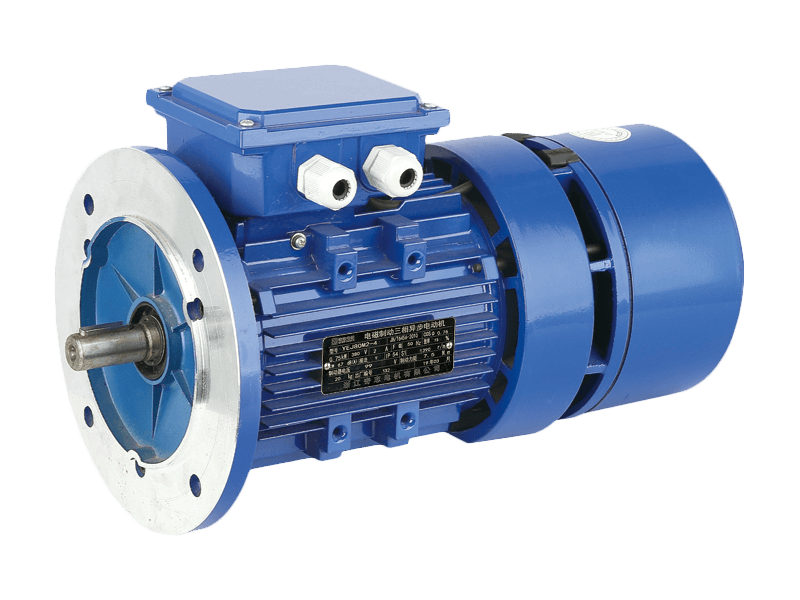

The design and construction of explosion proof motors are tailored to meet the specific challenges posed by hazardous environments. These motors are built with robust materials that can withstand harsh conditions, including bad temperatures and corrosive substances. The enclosures of explosion proof motors are sealed to prevent the ingress of dust and moisture, further enhancing their safety features. Additionally, these motors are rigorously tested to ensure they meet industry standards for explosion protection, providing peace of mind for operators in high-risk environments.

Another significant advantage of explosion proof motors is their versatility. They can be used in a wide range of applications across various industries, making them a valuable investment for companies looking to enhance safety. Whether in oil refineries, chemical plants, mines, or food processing facilities, explosion proof motors can be adapted to meet the specific needs of each operation. This adaptability allows businesses to implement safety measures without compromising on performance or efficiency.

Furthermore, the use of explosion proof motors can contribute to long-term cost savings. While the initial investment may be higher than standard motors, the reduction in accidents and downtime can result in significant financial benefits. Companies that prioritize safety by using explosion proof motors can avoid costly incidents, legal liabilities, and damage to their reputation. In the long run, investing in safety measures pays off by creating a more secure working environment and fostering a culture of safety within the organization.

In conclusion, explosion proof motors play a crucial role in ensuring safety across various industries, including oil and gas, chemical manufacturing, mining, and food processing. Their ability to operate safely in hazardous environments makes them an essential component of equipment used in these sectors. By understanding the importance of explosion proof motors and their applications, companies can enhance their safety protocols, protect their workforce, and comply with industry regulations. As industries continue to evolve and face new challenges, the demand for reliable and safe equipment, such as explosion proof motors, will remain a top priority for ensuring operational safety and efficiency.