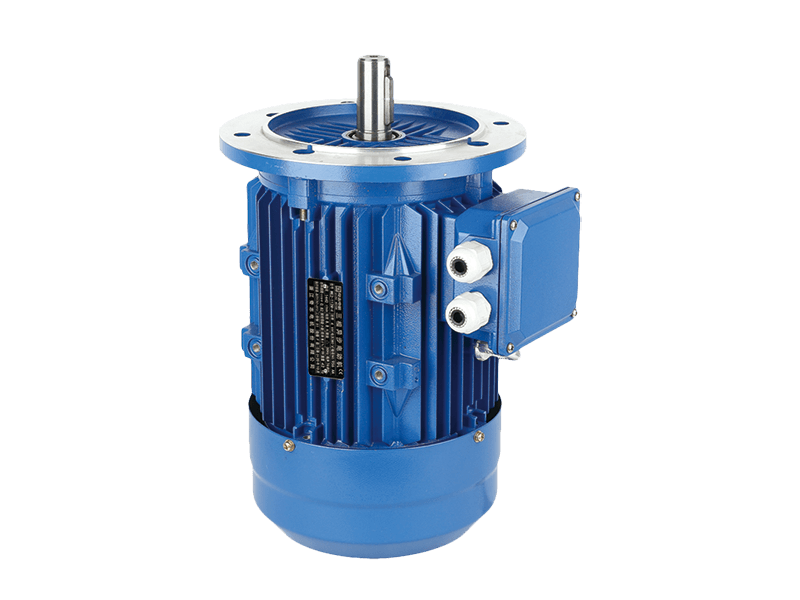

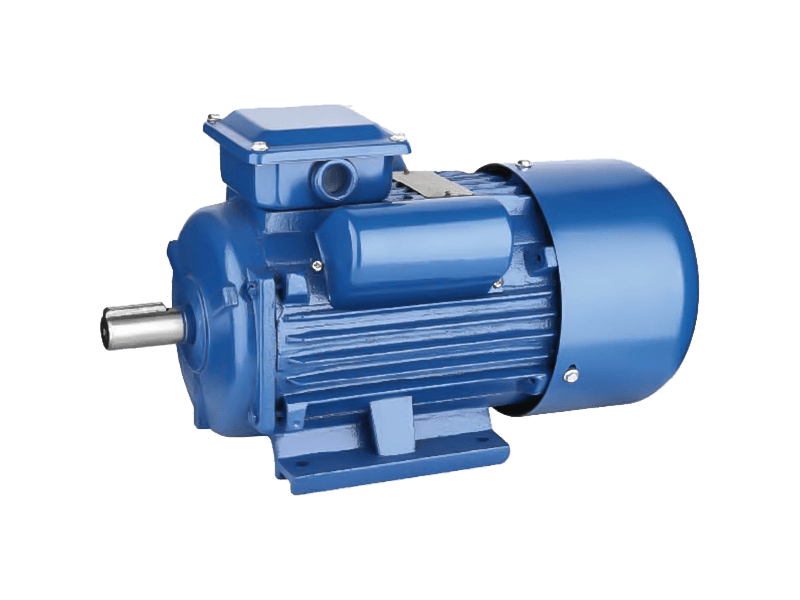

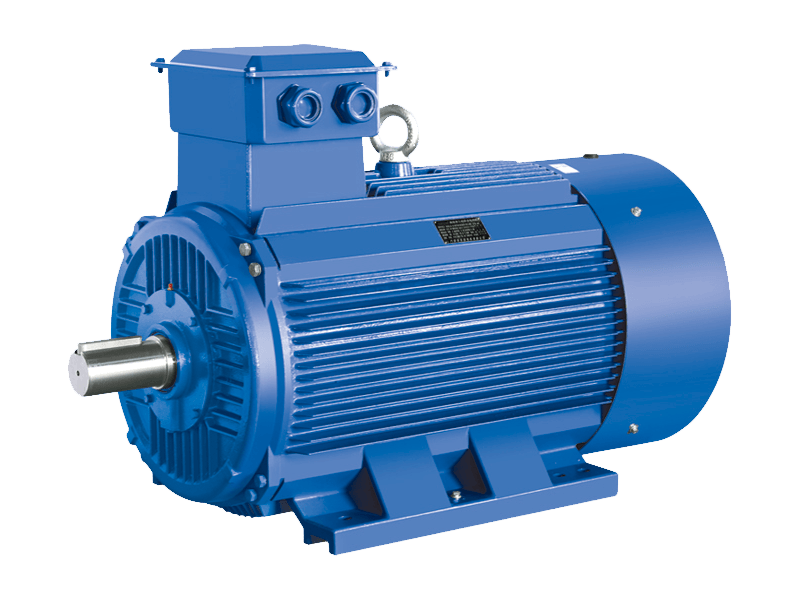

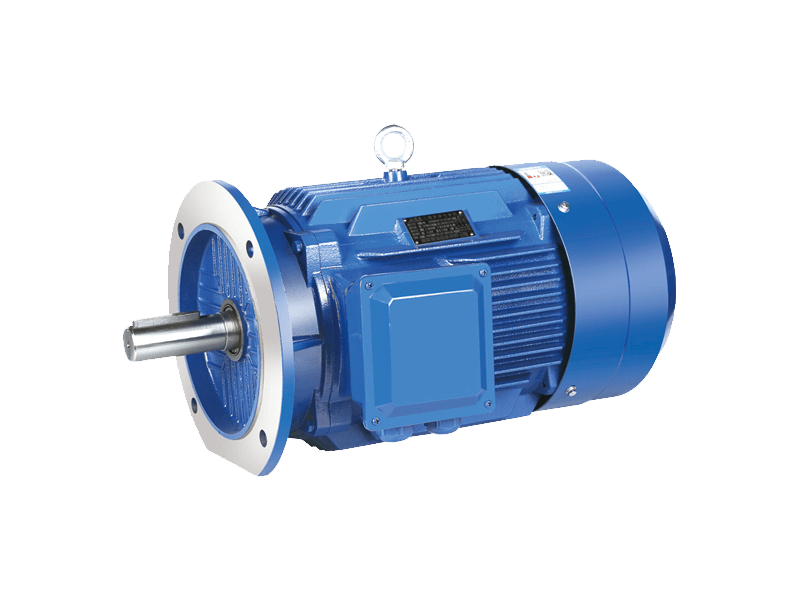

Brushless geared motors are becoming increasingly important in a variety of applications due to their unique characteristics.

In high-load applications such as industrial robots and heavy machinery, brushless geared motors are highly suitable. Industrial robots often need to perform tasks that require high torque. The brushless geared motor can provide the necessary power to move heavy parts or perform precise and force-intensive operations. For example, in an automotive manufacturing plant, industrial robots use brushless geared motors to lift and assemble large and heavy car components. These motors can generate high torque, which is crucial for handling such heavy loads. In heavy machinery, whether it is a construction crane or large-scale mining equipment, the brushless geared motor's ability to deliver high torque ensures that the machinery can operate effectively. The reliability of the brushless geared motor is also a key factor in these high-load applications. Since industrial robots and heavy machinery are often used continuously, any motor failure can cause significant downtime and losses. The brushless geared motor, with its robust design, can operate for long periods without breakdowns.

For applications where long-life operation is required, such as medical devices and automated production lines, brushless geared motors are a great choice. In medical devices, for instance, a brushless geared motor in a surgical tool needs to be able to function stably over a long time. This is because any malfunction during a surgical procedure can have serious consequences. The long-term stability of the brushless geared motor ensures that the medical device can be used repeatedly without the need for frequent motor replacements. In automated production lines, which may run for extended periods, the brushless geared motor can keep the production process going smoothly. It can maintain a consistent performance, which is essential for the quality and efficiency of the production line.

In applications where low maintenance is a priority, like remote monitoring devices and outdoor applications, brushless geared motors have distinct advantages. Remote monitoring devices are often located in hard-to-reach areas, and maintenance can be a challenge. The brushless geared motor has fewer parts that can wear out compared to some other types of motors. This means that it requires less frequent maintenance. In outdoor applications, such as in a weather station's equipment, the brushless geared motor can withstand harsh environmental conditions without the need for constant upkeep. The sealed design of the brushless geared motor can protect it from dust, moisture, and other environmental factors that could otherwise cause damage.

The brushless geared motor also offers other benefits in these applications. Its efficient operation helps to reduce energy consumption, which is important in both industrial and long-term operation scenarios. Additionally, the gear mechanism in the brushless geared motor can be adjusted to meet different torque and speed requirements, making it a versatile option for a wide range of applications.

In conclusion, brushless geared motors are well-adapted to high-load applications, applications requiring long-life operation, and those where low maintenance is crucial. Their ability to provide high torque, long-term reliability, and low - maintenance operation makes them an important component in various industries and applications. Whether it is on the factory floor, in the medical field, or remote outdoor installations, the brushless geared motor plays a significant role.